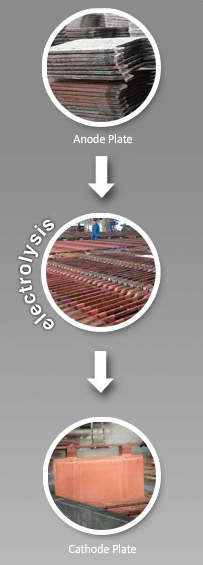

Copper is used mainly as an electrical conductor in industry. Electrical conductivity, the most distinguished property of copper, is improved to the required level by electrolytic refining in a tankhouse. The classical refining process at ER-BAKIR starts with melting blister copper and / or suitable copper scrap obtained from domestic and foreign sources in a Thomas type furnace. Natural gas is as fuel in the melting process. During the melting in Thomas furnace copper gives a typical green color to the flame The liquid copper gets the suitable form for loading into the electrolysis cells after solidification in the moulds. Electrolytic copper scrap arising at various stages in the plant can be reutilized in the refining. Copper is one of those few materials which can be recycled again and again.